The roof of a recreational vehicle is its first line of defense against the elements. It shields the interior from rain, snow, sunlight, and constant vibration during travel. A well-maintained roof ensures that the vehicle remains a reliable shelter on the road, while a failing roof leads to costly repairs and shortened service life. Choosing the right roof coating is one of the most important decisions an RV owner can make, because the coating determines how well the roof endures over years of exposure.

Understanding the demands of an RV roof

Unlike stationary structures, RVs face unique stresses. Every mile of travel shakes the roof, testing seams, adhesives, and joints. The constant movement exposes weaknesses that static buildings never encounter. Climate adds another layer of pressure. Ultraviolet rays break down rubber and fiberglass surfaces, while heat and cold create cycles of expansion and contraction that strain even the strongest membranes. Rainwater exploits small cracks, and if water reaches insulation or framing, the damage compounds quickly.

Traditional rubber and fiberglass roofs can handle these conditions for a time, but they require frequent sealing and patching. Owners often find themselves climbing ladders at the start of every season to reseal seams, apply new tape, or brush on another coat of sealant. This routine delays leaks but rarely prevents them altogether. For long-term protection, the coating must be more than a temporary fix. It must create a barrier that resists both movement and weather without breaking apart.

The importance of seamless protection

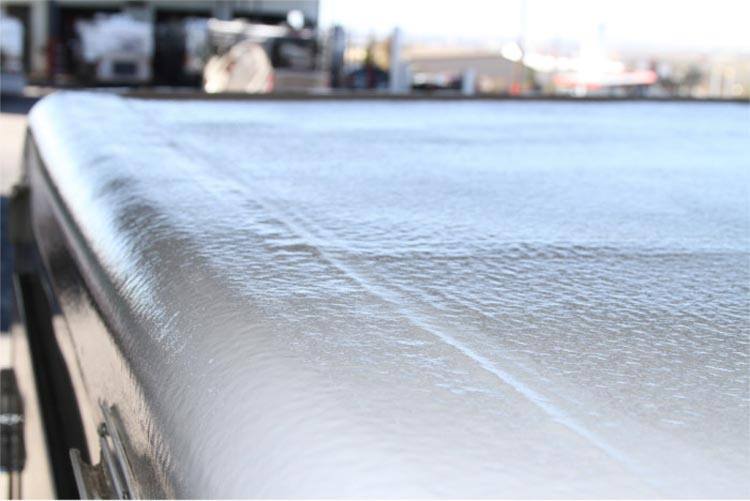

Roof coatings that provide long-lasting results share one feature: they eliminate seams. Seams are the weak points where leaks begin. When a coating can be applied seamlessly, it removes the very places where cracks usually form. Spray-applied systems achieve this by bonding directly to the roof substrate, covering every curve and fixture with a continuous layer. Once cured, the coating becomes part of the roof itself, not just an added layer.

The best modern coatings are formulated from polyurea, an elastomer known for both durability and flexibility. Polyurea stretches with the roof as it flexes during travel or expands under summer heat. Unlike rigid coatings that resist movement until they fracture, polyurea adapts and recovers, maintaining a watertight seal. It also resists ultraviolet degradation, preventing the chalking and brittleness that shorten the life of other products.

Comparing conventional and advanced coatings

Acrylic and silicone-based roll-on coatings remain common because they are inexpensive and easy to apply. They can refresh a roof for a season or two, but they often peel under long exposure to sunlight and require frequent reapplication. Rubber-based systems provide elasticity, but they lose their flexibility as they age and become prone to cracks. Fiberglass coatings resist abrasion but lack the flexibility needed to withstand constant vibration.

In contrast, polyurea-based rv roof coatings offer a balance of strength and adaptability that makes them well-suited for mobile structures. They bond tightly, cure rapidly, and resist both weather and movement. Instead of planning for another repair in a year, owners gain confidence that their roof will hold up for the long term.

Practical benefits for owners

The strength of a coating reveals itself not only in how it handles storms but also in how it reduces maintenance. Owners who switch to polyurea systems notice the difference when they no longer need to reseal seams or apply patches at the start of each season. The roof simply holds. That reliability translates into savings, because avoiding water damage prevents the expensive repairs that follow leaks—repairs that often require tearing out interior walls, replacing insulation, and rebuilding framing.

A strong coating also improves comfort during travel. By reflecting heat and resisting moisture, it helps regulate interior temperature and keeps the living space dry. This stability makes the RV more livable for those who spend extended time on the road.

Why choosing the right coating matters

Roof failures rarely occur in convenient places. They often happen in the middle of a trip, far from repair shops or replacement parts. By choosing a coating built for long-term performance, owners avoid these disruptions and travel with peace of mind. The roof becomes a trusted part of the vehicle rather than a constant source of worry.

The decision also affects resale value. An RV with a solid, well-protected roof maintains its value far better than one with a history of leaks and water damage. For buyers, a sound roof is a sign that the vehicle has been cared for and that its interior has remained protected.

Conclusion

When considering the best RV roof coatings for long-lasting protection, the evidence points to materials that combine seamless application with elasticity and weather resistance. While traditional coatings offer temporary solutions, polyurea-based systems stand out as the option that truly prevents failure rather than delaying it. They turn the roof into a stable barrier that resists cracks, leaks, and ultraviolet damage across years of use.

For RV owners who want to spend more time traveling and less time repairing, investing in a high-performance roof coating is not just practical—it is essential. The right choice transforms the roof from a liability into an asset, ensuring that the vehicle remains a safe and reliable home wherever the road leads.