Owning an Airstream means relying on a shell of metal to protect the inside of your travels. The polished exterior may carry a sense of nostalgia, but it also serves a functional role. It reflects heat, channels rain, and holds up against wind. The roof, though part of that continuous surface, faces more stress than any other part of the trailer. UV radiation, tree sap, heat cycling, and debris all wear down its resistance. That’s why protecting it is less about looks and more about preventing failure before it starts.

Why the Airstream Roof Matters More Than You Think

The curved aluminum shell of an Airstream has earned its reputation for durability, but it does not seal itself. Seams, rivets, and vents create natural vulnerabilities. Over time, the butyl tapes and sealants used at these joints lose flexibility. Water begins to find its way in. The roof, by design, deflects runoff rather than absorbing it, but any failure in that deflection turns into long-term damage inside the trailer.

Leaks rarely appear with drama. They show up as soft walls, lifting veneer, or a musty smell that doesn’t leave. These signs often surface long after the water has done its work. Preventing this means focusing not only on the visible surface, but on what protects the joints, the sealants, and the structure beneath.

Coating as a Preventative Measure, Not a Fix

Airstream roofs differ from standard rubber or fiberglass RV roofs. They don’t use a membrane stretched over plywood. Instead, the metal itself forms both structure and exterior. This distinction changes how one should approach roof protection. Liquid-applied coatings must bond to aluminum, handle thermal expansion, and resist UV breakdown for years without delaminating.

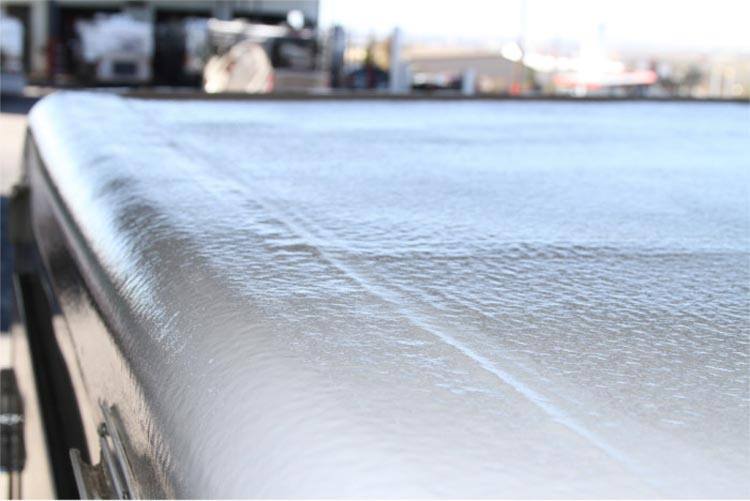

A good roof coating keeps the seams sealed, bridges small gaps, and creates a waterproof layer that expands and contracts with the metal below it. Unlike tapes or caulks that depend on edge adhesion, a sprayed coating covers the full surface in a single system. That continuity helps reduce points of failure. It also provides insulation against radiant heat, which aluminum roofs absorb more readily than other materials.

Spray-applied systems based on polyurea or hybrid technologies now play a growing role in this work. These materials cure quickly and resist cracking, chalking, or softening over time. Their use has expanded beyond industrial tanks and rooftops into RVs because of their ability to stay flexible and waterproof under shifting conditions.

Preparing for Long-Term Roof Performance

Applying a coating to an Airstream roof requires more than cleaning the surface and spraying it down. Surface preparation matters. Oxidized aluminum must be etched or scuffed. Old sealants need to be removed or covered in a compatible primer. The applicator must consider how each vent, solar bracket, or air conditioner integrates into the coating system.

The process does not erase the roof’s design but reinforces it. The goal is not to build something new, but to make the existing material last longer. When done correctly, the result is not noticeable by sight but by performance. Rain runs off without pooling. Heat reflects instead of transmitting. Most importantly, the joints stop failing quietly.

In field testing and application feedback featured in Polyurea Magazine, polyurea-based coatings have shown durability in outdoor environments that match or exceed what an Airstream roof will face. The research does not suggest a cure-all, but it does point to coating systems as a long-term strategy rather than a last-minute fix.

Choosing the Right Approach to RV Roof Care

Protecting an Airstream roof is not about overbuilding. It’s about reinforcing what works. The roof already has strength. It already deflects rain and wind. What it lacks, over time, is flexibility in its sealants and uniformity in its weather protection. Coating fills that gap.

This approach fits into a broader view of RV care—one that prioritizes prevention over repair. While the body of the trailer may shine with polish and reflect the sunlight, it’s the roof that takes the beating. It’s the roof that needs to flex, seal, and last through every season.

Thinking this way helps owners plan better. It shifts the focus from reacting to water stains or soft spots to avoiding them entirely. With that shift, a coating becomes not a product, but a practice. A method of extending service life. A way to keep the travel going.

Conclusion: Let the Roof Do Its Job

An Airstream roof doesn’t need to be rebuilt. It needs to be maintained in a way that respects its structure. With a proper coating, it can continue to reflect, resist, and move without compromise. It can stop becoming the source of slow, hidden problems and remain what it was designed to be—a shelter that moves with you and keeps your space dry, quiet, and clean.

In the end, protection doesn’t have to be complicated. But it does have to be thoughtful. And the roof, though easy to ignore, will always be the first place that shows whether that thoughtfulness was put to use.