Owners must ensure an RV roof’s durability and ease of upkeep.This has led to a shift towards embracing advanced solutions, like polyurethane spray-on coatings, which outperform the conventional options of rubber and fiberglass in terms of reliability and longevity.

Rubber roofs crafted from EPDM (ethylene propylene diene monomer) have been a popular choice for RVs for years due to their flexibility, which allows them to endure the usual movement and shifting in recreational vehicles (RVs). Nevertheless, rubber roofing has its restrictions, as prolonged exposure to UV rays, weather conditions, and debris can lead the rubber material to deteriorate over time. This deterioration may result in the formation of cracks and tears which could cause leaks necessitating repair or even a full roof replacement. Rubber roofs also have a tendency to gather dirt over time and require effort to keep clean; moreover, their proneness to punctures presents a continuous concern, for those who own RVs.

Regarding roofing materials for RVs, fiberglass roofs are also popular due to their sturdiness compared to rubber roofs. People often praise them for their appearance and resistance to water penetration. However fiberglass does have its drawbacks. One of the concerns with using fiberglass for roofing is its tendency to develop cracks over time. The inflexible properties of fiberglass mean that as an RV moves, across ground the pressure can result in roof fractures. The presence of these fissures doesn’t just affect the roofs waterproofing capabilities. Also results in expensive maintenance work to be done later down the line. Moreover fiberglass roofs are susceptible, to delamination, which occurs when the layers of the material start to separate thereby causing structural weakening.

Polyurea coatings provide an long lasting option that outperforms rubber and fiberglass materials in terms of durability and flexibility. A key advantage of polyurethane is its capacity to create an protective layer without any breaks or seams. When used on the roof of an RV polyurethane coating sticks to the surface forming a seamless shield that prevents potential weak spots where leaks or harm might start occurring. Polyureas are known for their durability and ability to withstand UV rays and harsh conditions without deteriorating like rubber or fiberglass might.

Polyureathanes versatility is a standout feature that distinguishes it from materials like rubber because it can stretch and contract along with the movements of an RV without the concern of tearing or deteriorating over time.This elasticity makes polyureathane coatings particularly useful for RVs that encounter weather conditions such as hot and sunny or cold and damp environments.The coating forms a protective barrier that remains strong and intact, over time to keep the roof secure and leak free for many years to come.

Polyureas have an advantage over traditional methods due to their ability to withstand punctures and abrasions effectively in comparison to materials like rubber or fiberglass commonly used for RV roofs that are more susceptible to damage from branches and rocks during travel trips. The durability of polyureas offers a layer of protection against such environmental elements making it a preferred choice, for RV owners who often traverse off road terrains or rough landscapes.

Polyurethane coatings stand out in the maintenance department well compared to traditional rubber and fiberglass roofs that often necessitate periodic cleaning and resealing to uphold their efficiency levels or patching up when needed due to dirt buildup or delamination issues respectively. On the contrary polyurethane coated roofs require effort for upkeep with their seamless coating that hinders dirt accumulation and their resistance, to mold and mildew. Common problems found in conventional roofing materials. If RV owners opt for polyurethane coating on their roofs of other options available in the market today like rubber or silicone based coatings; they may notice that it demands less attention in terms of maintenance, over time which can ultimately lead to savings in both time and money.

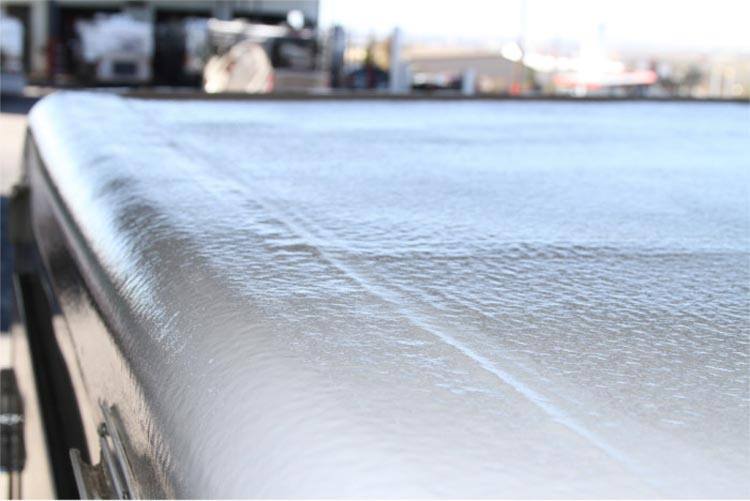

Moreover polyurethane coatings are able to be put on roofs presenting themselves as a flexible choice for RV owners seeking to enhance their vehicle without having to fully replace the roof. The coating is easily sprayed on top of rubber or fiberglass offering a level of shield that boosts the longevity and efficiency of the roof. This capacity to upgrade existing roofs makes polyurethane a desirable choice, for individuals aiming to prolong the lifespan of their RV without incurring the costs of a roof renovation.

In essence polyureaspray on coatings offer benefits compared to traditional rubber and fiberglass roofing materials used in RVs.With the ability to be applied seamlessly and its flexibility,resistance to damage and minimal maintenance needs polyureapresents a top notch option for RV owners looking for lasting roof protection.As an increasing number of individuals opt for polyureabecause of its established effectiveness it’s evident that this advanced technology will remain pivotal, in shaping the future of RV roofing.